A few weeks ago the Serial Set team here at Dartmouth went down to Chester, Vermont for our annual Serial Set Project meeting and got to spend most of the day with our partners at Readex! I was able to go down in November shortly after I started here in Preservation Services, but this was Elizabeth Rideout's first visit. So we got to go on a nice tour.

At any given time, Readex is undergoing several different projects, while working toward putting out into the world an assortment of databases jam-packed with information from a variety of sources. My particular interest with Readex is with the U.S. Congressional Serial Set, as this is the set of books that myself and Ms. Rideout work on. So while Readex has many different aspects of production, I'm going to focus selfishly on what I consider to be my favorite.

Readex Operations, disguised by a humble New England exterior, but what lies behind these walls is nothing short of astounding. Pictured from left to right Elsa Lamphere (my direct contact at Readex), Elizabeth Rideout (my partner in crime), Deborah Howe (the chief, directly oversees any and all repairs by Elizabeth and me), and Vicky Gardner (Vice President, Editorial).

After some warm 'Hellos' we're taken into the depths of the Readex production line. This is where the process starts.

A temperature and humidity controlled holding room for the Serial Set to rest in while they wait to be scanned, packed or double checked. Each truck arrives, is checked in and is assigned a special number that only Readex knows.

Elsa explains to Elizabeth the way that each volume is flagged and tagged throughout the scanning process. (Look at all those Serial Set books in the back ground! Readex sure is working hard!)

Once the Serial Set volumes are flagged and given their unique ID numbers, they are scanned, one page at a time by an incredible piece of technology! A KIRTAS Machine! (Watch this amazing video to see how it actually moves! Video NOT taken at Readex)

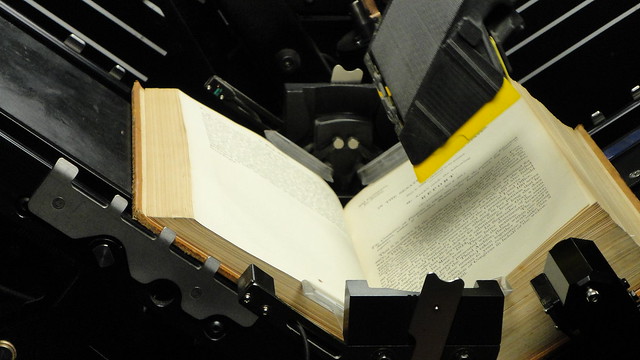

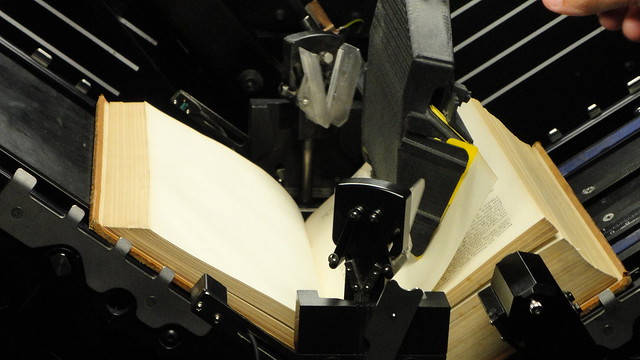

The technician places the volume in the machine and lines up the clamps just right, this way the machine can do its thing without a lot of re-adjusting and without damaging the book.

The machine then takes over for the most part. There is a vacuum arm (with yellow around the edge) that reaches over and turns the pages, at the top of the machine is a camera and two mirrors that photographs each page when the book is open. The cradle that the book is resting in is adjustable and the technician does just that as the pages are turned and weight is distributed differently. This prevents any stress on the spine as well as unnecessary strain on the shoulders and boards of the volume. There are several other features that the Kirtas utilizes to keep the process going smoothly including a small air jet called a 'fluffer' that blows to keep the pages from sticking to each other, small clear clamps that hold the book open, and direct download to a computer as the machine photographs.

The following is the sequence as the machine turns a page!

After the volumes are scanned, the images are checked by technicians for quality control. Sometimes there's a hand in the scan, sometimes they missed a page, or sometimes the camera just didn't photograph the right side. Once all the images are okay, they send these to the Index-ers. These folks READ all of the Serial Set books and index the content! Incredible! The product goes through several more steps to insure its accuracy and usability, and then it's released to the customers.

Thank you so much for the tour, Readex! As always, we here at Dartmouth had a wonderful time.

Photos and Writing by Beth Hetland

No comments:

Post a Comment